NEWS

Application of hollow board in cell packaging industry

2020-04-23 16:33

The sun is a huge energy source. It emits about 3.8 × 10 20 MJ of energy into space every second in the form of light radiation, and one-two-two billionth of it is projected onto the earth. Solar cells can directly convert light energy into electrical energy through the photoelectric effect, but the material is brittle, and bumps, shocks and vibrations are encountered during transportation, plus brutal handling. The fragmentation rate of the solar cells is quite high. The fragmentation rate of solar cells is an important indicator to measure the technical level of an enterprise, and another important indicator is the oxidation resistance of packaging materials for products. With the continuous development of technology and the continuous innovation of packaging materials, it is necessary to constantly update the original packaging solutions. In this paper, the transportation packaging of solar cells is taken as the research object. The corrugated carton packaging currently used is compared with the hollow board turnover box packaging to discuss the practicality of the hollow board turnover box for the cell sheet packaging.

1. Material information of hollow board

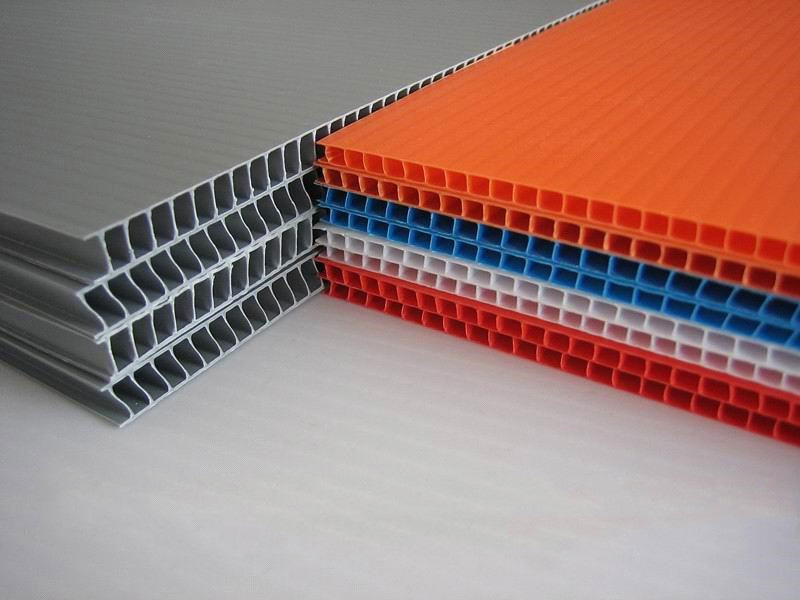

Hollow board is a polypropylene raw material blended with polyethylene raw material and extruded through a hollow board production line. The section of the board is a lattice shape (see Figure 1), so it is also called a lattice hollow board. The particularity of its material determines its non-toxic, non-polluting, corrosion-resistant, waterproof, and shock-proof performance. At the same time, some factories can blend masterbatch with different properties according to different requirements, making it a higher performance hollow board. For example, when it is blended with flame-retardant masterbatch to become a flame-retardant hollow board, it can be used in areas with high fire-resistance requirements. As a new type of environmentally friendly packaging material, hollow board will not generate dust during use and has a long service life.

Second, the transport packaging design of the battery

1. Product information of battery cells. Battery cells are generally divided into three types: monocrystalline silicon, polycrystalline silicon, and amorphous silicon. Monocrystalline silicon solar cells are currently the fastest-growing solar cells. The surface is dark blue silicon wafers. The screen printing method is used to print the well-matched silver paste on the silicon wafers to form grid lines. The size of the battery is 165 mm × 165 mm, and the thickness is 0.03 mm. The main requirements of the packaging are anti-oxidation, anti-static, anti-scratch, anti-vibration, anti-shock, and the product cannot bear its own weight.

2. Packaging design of battery

Considering the thin and brittle characteristics of the battery, when selecting the horizontal packaging form, the hollow plate turnover box is designed according to the size of the existing battery, using a one-piece structure. The battery sheet is placed flat in the hollow board turnover box. This method increases the contact area between the battery sheet and the hollow board turnover box, thereby improving the cushioning performance of its packaging. Due to the small size of the hollow board turnover box itself, in order to support the entire package, it is more appropriate to choose a hollow board with a thickness of 3 mm as the packaging material of the box.

3. The characteristics of the hollow board turnover box in the cell packaging

According to the particularity of the cell packaging requirements, comparing the corrugated carton, the applicability of the hollow board turnover box will be explained through the following points.

1) Fragmentation rate. The fragmentation rate of the cell is an important indicator to measure the level of packaging technology. Therefore, field experiments are carried out in a photovoltaic enterprise factory. Take a whole tray of batteries as the test unit (1 tray is a whole tray of packaged products, using a 2 × 2 × 3 stacking method, then 1 tray can hold 12 boxes, one box contains 12 boxes of batteries, one box There are 100 cells in it), which are packed in corrugated carton and hollow board turnover box, that is, 1 tor of corrugated paper and 1 tor of hollow panel. Through the logistics transportation method of trucks, from Shaanxi to Shanghai, and then from Shanghai to Shaanxi, the total logistics time is about 4 days. After being shipped back, unpacking inspection revealed that 21 pieces of cells packed in a corrugated carton were broken pieces, and the breakage rate was 0.1458%; only 4 pieces of batteries packed in a hollow box turnover box were broken pieces. The fragmentation rate was 0.0277%. Although both of the above two schemes meet the requirements of enterprises that the fragmentation rate should be less than 0.4%, compared with the fragmentation rate, the hollow plate packaging box is more suitable for battery pack packaging.

2) Anti-oxidation. The most common oxidation is mainly due to air and water, and for the packaging of battery cells, water and air are most in need of isolation. As a major solar energy manufacturing country in China, solar cells must be exported. Taking export to South Africa as an example, in order to save transportation costs, ships are generally selected for transportation. The environmental conditions at sea are generally extremely harsh, and many uncontrollable factors make the sea The transportation requirements for packaging are particularly high. However, corrugated paper will deform when it is exposed to water, its compression resistance and oxidation resistance will be greatly reduced, and its recovery is poor. Compared with the corrugated carton, the hollow board turnover box is more suitable for these harsh environments because of its lighter material and waterproof characteristics.

3) Anti-static. Because the hollow board material itself cannot be anti-static, it can only use anti-static foam to avoid the impact of static electricity on photovoltaic products. Both the new and old schemes use the method of adding XPE foam. XPE can not only prevent static electricity, but also It acts as a buffer to protect the product. XPE foam is polyethylene foam. Because it contains antistatic agents, it is widely used in fragile products that are sensitive to static electricity, such as automobiles, navigation, and construction.

4) Cost analysis. After market price analysis, the cost of a 180 mm × 180 mm × 50 mm corrugated carton is about 1.72 yuan. It is generally scrapped after 1 to 2 times, and the cost per use is about 0.86 yuan / time. The hollow box of the same size needs 3.2 yuan, but because the service life of the hollow board is longer, it is generally 4 to 10 times the life of the corrugated board. Therefore, if the hollow board is used more than 4 times, the cost per time is 0.8 yuan. It saves 6.98% of the cost of corrugated carton. If it is used more than 10 times, the cost per time is 0.32 yuan, which is 62.79% less than the cost of corrugated carton. It can be seen that compared with corrugated boxes, for some long-term customers, the hollow board is generally used to save costs, and for one-time customers, the corrugated boxes are more cost-effective.

Hollow board, as a new type of environmentally friendly packaging material, compared with corrugated carton, which is widely used at present, has outstanding advantages in the fragmentation rate and oxidation resistance of cell packaging. In terms of cost analysis, the price of hollow board turnover box is slightly higher than that of corrugated carton. However, as a recyclable material, considering the logistics price and the number of reuses, the hollow board turnover box is also more suitable for the packaging of battery cells. At the same time, the hollow board turnover box can produce different colors, compared with the unity of the color of corrugated carton packaging, it is more suitable for the choice of the times.

1. Material information of hollow board

Hollow board is a polypropylene raw material blended with polyethylene raw material and extruded through a hollow board production line. The section of the board is a lattice shape (see Figure 1), so it is also called a lattice hollow board. The particularity of its material determines its non-toxic, non-polluting, corrosion-resistant, waterproof, and shock-proof performance. At the same time, some factories can blend masterbatch with different properties according to different requirements, making it a higher performance hollow board. For example, when it is blended with flame-retardant masterbatch to become a flame-retardant hollow board, it can be used in areas with high fire-resistance requirements. As a new type of environmentally friendly packaging material, hollow board will not generate dust during use and has a long service life.

Second, the transport packaging design of the battery

1. Product information of battery cells. Battery cells are generally divided into three types: monocrystalline silicon, polycrystalline silicon, and amorphous silicon. Monocrystalline silicon solar cells are currently the fastest-growing solar cells. The surface is dark blue silicon wafers. The screen printing method is used to print the well-matched silver paste on the silicon wafers to form grid lines. The size of the battery is 165 mm × 165 mm, and the thickness is 0.03 mm. The main requirements of the packaging are anti-oxidation, anti-static, anti-scratch, anti-vibration, anti-shock, and the product cannot bear its own weight.

2. Packaging design of battery

Considering the thin and brittle characteristics of the battery, when selecting the horizontal packaging form, the hollow plate turnover box is designed according to the size of the existing battery, using a one-piece structure. The battery sheet is placed flat in the hollow board turnover box. This method increases the contact area between the battery sheet and the hollow board turnover box, thereby improving the cushioning performance of its packaging. Due to the small size of the hollow board turnover box itself, in order to support the entire package, it is more appropriate to choose a hollow board with a thickness of 3 mm as the packaging material of the box.

3. The characteristics of the hollow board turnover box in the cell packaging

According to the particularity of the cell packaging requirements, comparing the corrugated carton, the applicability of the hollow board turnover box will be explained through the following points.

1) Fragmentation rate. The fragmentation rate of the cell is an important indicator to measure the level of packaging technology. Therefore, field experiments are carried out in a photovoltaic enterprise factory. Take a whole tray of batteries as the test unit (1 tray is a whole tray of packaged products, using a 2 × 2 × 3 stacking method, then 1 tray can hold 12 boxes, one box contains 12 boxes of batteries, one box There are 100 cells in it), which are packed in corrugated carton and hollow board turnover box, that is, 1 tor of corrugated paper and 1 tor of hollow panel. Through the logistics transportation method of trucks, from Shaanxi to Shanghai, and then from Shanghai to Shaanxi, the total logistics time is about 4 days. After being shipped back, unpacking inspection revealed that 21 pieces of cells packed in a corrugated carton were broken pieces, and the breakage rate was 0.1458%; only 4 pieces of batteries packed in a hollow box turnover box were broken pieces. The fragmentation rate was 0.0277%. Although both of the above two schemes meet the requirements of enterprises that the fragmentation rate should be less than 0.4%, compared with the fragmentation rate, the hollow plate packaging box is more suitable for battery pack packaging.

2) Anti-oxidation. The most common oxidation is mainly due to air and water, and for the packaging of battery cells, water and air are most in need of isolation. As a major solar energy manufacturing country in China, solar cells must be exported. Taking export to South Africa as an example, in order to save transportation costs, ships are generally selected for transportation. The environmental conditions at sea are generally extremely harsh, and many uncontrollable factors make the sea The transportation requirements for packaging are particularly high. However, corrugated paper will deform when it is exposed to water, its compression resistance and oxidation resistance will be greatly reduced, and its recovery is poor. Compared with the corrugated carton, the hollow board turnover box is more suitable for these harsh environments because of its lighter material and waterproof characteristics.

3) Anti-static. Because the hollow board material itself cannot be anti-static, it can only use anti-static foam to avoid the impact of static electricity on photovoltaic products. Both the new and old schemes use the method of adding XPE foam. XPE can not only prevent static electricity, but also It acts as a buffer to protect the product. XPE foam is polyethylene foam. Because it contains antistatic agents, it is widely used in fragile products that are sensitive to static electricity, such as automobiles, navigation, and construction.

4) Cost analysis. After market price analysis, the cost of a 180 mm × 180 mm × 50 mm corrugated carton is about 1.72 yuan. It is generally scrapped after 1 to 2 times, and the cost per use is about 0.86 yuan / time. The hollow box of the same size needs 3.2 yuan, but because the service life of the hollow board is longer, it is generally 4 to 10 times the life of the corrugated board. Therefore, if the hollow board is used more than 4 times, the cost per time is 0.8 yuan. It saves 6.98% of the cost of corrugated carton. If it is used more than 10 times, the cost per time is 0.32 yuan, which is 62.79% less than the cost of corrugated carton. It can be seen that compared with corrugated boxes, for some long-term customers, the hollow board is generally used to save costs, and for one-time customers, the corrugated boxes are more cost-effective.

Hollow board, as a new type of environmentally friendly packaging material, compared with corrugated carton, which is widely used at present, has outstanding advantages in the fragmentation rate and oxidation resistance of cell packaging. In terms of cost analysis, the price of hollow board turnover box is slightly higher than that of corrugated carton. However, as a recyclable material, considering the logistics price and the number of reuses, the hollow board turnover box is also more suitable for the packaging of battery cells. At the same time, the hollow board turnover box can produce different colors, compared with the unity of the color of corrugated carton packaging, it is more suitable for the choice of the times.

Service Hotline:

Mr Wang:+86 13031791835

E-mail:info@cnyufengplastic.com

Add:No.8,Zichai Road,Hutian Street,ZhangdianDist,Zibo City,Shandong Province,China

Copyright © 2020 Shandong YouFul Plastic Co, Ltd All Right Reserved 鲁ICP备19019079号-2